- Hydrogen generator kit

- About Us

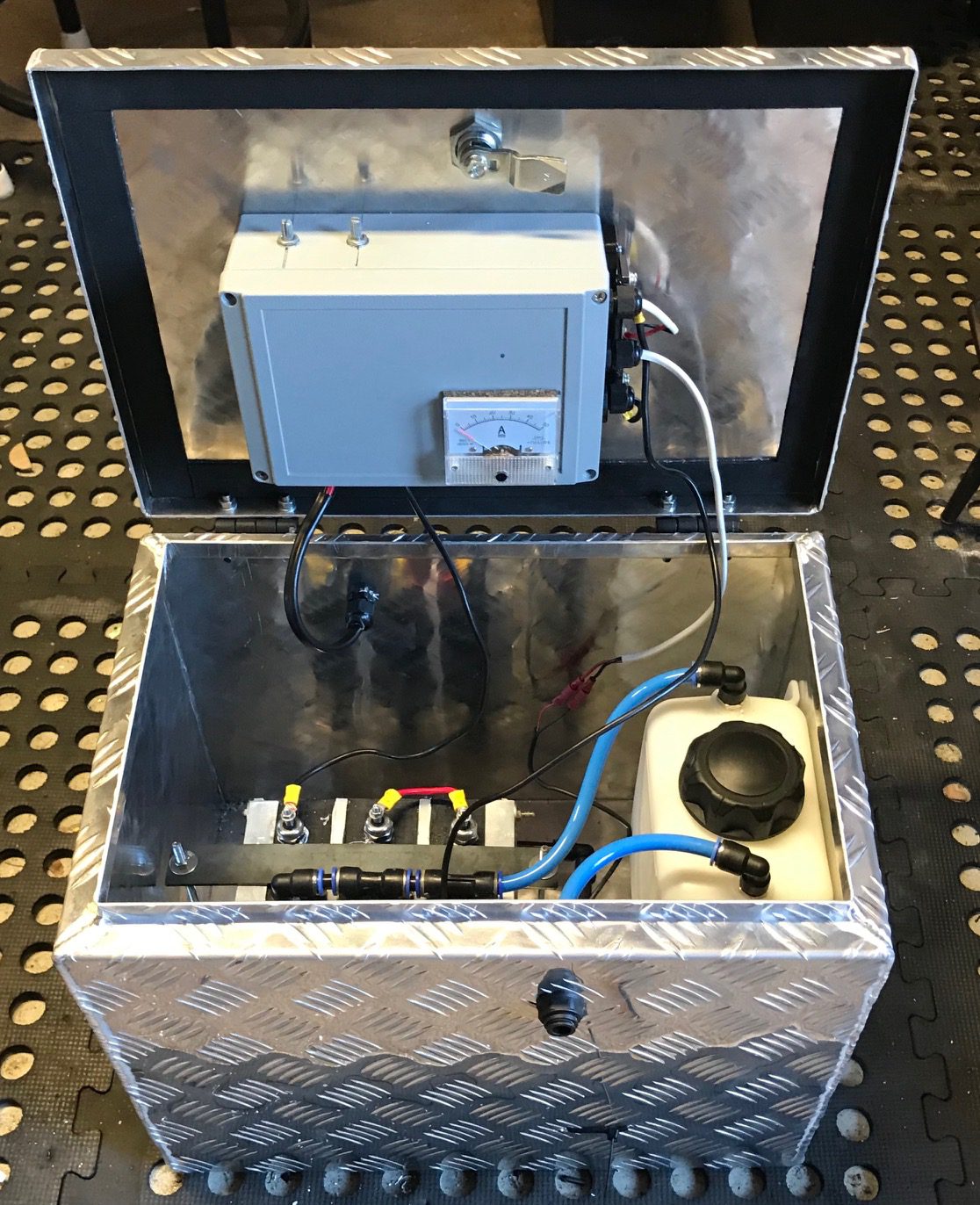

- HHO Kits

- Gen 10 Specifications Sheet hydrogen kits for cars

- Gen 15 Specifications Sheet

- Gen 20 (G20) Hydrogen Fuel System:

- Hydrogen Kit for your Truck, Boat, Generator

- Hydrogen Generator Kits for Cars

- Hydrogen kits and Test results

- Details Hydrogen Kits Gen 10, Gen 15, Gen 20 systems

- Work Applicationsof hydrogen kits

- Shop Hydrogen

- Photos, Resources

- HHO Products, Summary and Research

- Fuel savings Excel spreadsheet

- Installation Instructions cars, trucks,

- PWM and EFIE Installation Instructions Petrol engines

- Installation and Operation of a MAP/ MAF sensor enhancer

- Image Gallery

- USA Department of Energy

- Videos

- Publications, Text References and Authors

- Posts

- Newsletter

- TERMS and CONDITIONS

- Summary of Benefits of using Hydrogen Generator kits

- Testimonials

- Coogee chemicals Trucking Gen 20 Hydrogen systems may 2012

- Coogee chemicals Trucking Gen 20 Hydrogen systems may 2015

- Gail Brenan Gen 15 Hydrogen system March 2017

- Fred Hermon 2018 Gen 10 System Hydrogen generator kits

- Kevin Brookes June 2019 Gen 15 Hydrogen system

- Testimonial Tracker Prance October 21 2021

- Testimonial Troy Lahey Feb 2021

- Troy Lahey February 2021

- Paul Morris Gen 15 Hydrogen system 2014

- Paul Laird 2014 Gen 20 System Hydrogen generator

- Kevin Brooks Sept 2021 Gen15 Hydrogen Generator saves fuel

- Bob Bishop June 2015 Gen 15 Hydrogen system and Gen 10 Hydrogen system

- Orders

- PayPal payments

- HHO Manual

-

Perth, West Australia

- +61-0403177183

- glknox11@live.com