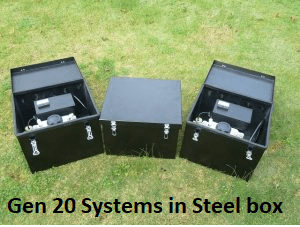

Brilliant Invention Gen 20 Hydrogen Generator

Brilliant Invention Gen 20 Hydrogen Generator ---update Feb 7... Full Story

Perth, West Australia

October 10 2022

Updated March 7, 2025

Electrolyte setup for Hydrogen . Commonly, individuals attempt to increase the gas production by increasing the strength of an electrolyte solution. Hydrogen gas is produced from the oxidation/ reduction reaction of the Hydroxide ions (OH–) which are present in the water. Increasing the concentration of the hydroxide ions (OH–) in the water makes more ions available for this reaction.

Pure water has a concentration of hydroxide ions (OH–) which is only one ten millionth of a mole of ions per litre. Consequently pure water is a Non conductor of electricity.

By adding Potassium Hydroxide crystals (Potash Soda) to water significantly increases this (OH–) hydroxide ion concentration and increases the conductivity of the water. The Logic is that the greater the Hydroxide ion concentration then the more gas that should be able to be produced in a linear scale.

However the greater the hydroxide ion concentration the lower the electrolyte resistance and the greater the amount of current flow that is possible.

In the Hydrogen electrolysis cell attached to a vehicles 12 volt battery (13.8 Volt alternator) there will always be overvoltage applied as the applied voltage is closer to 13.8 volts from the alternator. The over voltage gives rise to generation of heat which heats the liquid and lowers the cell internal resistance allowing more and more current to flow. The increasing thermal energy is related to the formula Power = Current squared x resistance. The electrical power lost as heat is not a linear scale but dependent upon the square of the current flow.

Power lost as heat = current squared x internal resistance

Simplifying the situation it is found the best solution is the use a small quantity of potassium hydroxide and allow the solution / systems to run for 15 minutes to heat the solution, reduce the circuit resistance until the systems reach equilibrium so that it reduces the waste of electrical energy as Heat

For our tests over a range of different size systems, and input battery voltages ( as can be seen on the attached Charts) it was found the optimal electrolyte concentration was 4 grams of Potassium hydroxide per litre of water in the original solution. This generates 3.2 litres of gas per minute after the solution has warmed to 56 Celsius and reached equilibrium.

These tests were done using my 3 litre recycling tank which holds the potassium hydroxide electrolyte.

Changing the tank size, and material used to construct the tank will change the equilibrium position, thereby altering the initial amount of electrolyte required.

Or the past 6 months we have been Operating Gen 20 systems on a number commercial trucks with over 100,000 km travelled. It has shown it best to use a small amount of electrolyte when setting up the electrolysis system so as to reduce the amount electrical energy wasted as heat – and generate more hydrogen gas. The reported savings on a number of Trucks are between 17 % and 25% on heavy haulage.

Brilliant Invention Gen 20 Hydrogen Generator ---update Feb 7... Full Story

Drop in oil price and Hydrogen. April 22 2020... Full Story

Effects of Hydrogen Addition on Power and Emissions Outputs... Full Story

Improvement of performance and reduction of pollutant emission of... Full Story

Hydrogen Fueled Internal Combustion Engine: A Review November 27... Full Story

Payment Methods Partner:

© 2023 - Hydrogenfuelsystems pty ltd