Brilliant Invention Gen 20 Hydrogen Generator

Brilliant Invention Gen 20 Hydrogen Generator Oxy-Hydrogen gas is... Full Story

Perth, West Australia

The Common question “ How does Hydrogen Help Improve my engine Fuel economy , Power and torque can be answered with the following report and information about the Properties of Hydrogen Gas.

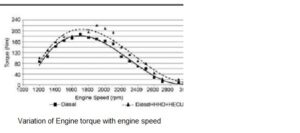

Fig. 1 shows the variation of engine torque with engine speed. An average of 19.1% increment in engine torque is obtained with using HHO system compared to pure diesel operation.

The increase in power is due to oxygen concentration of hydroxy gas and better mixing of hydroxy with air and fuel that yield enhanced combustion. High laminar flame velocity of hydroxy yields decreased ignition delay and shorter combustion period that provides lower heat losses, much closer to ideal constant-volume combustion which results increased compression ratio and thermal efficiency.

High burning velocity of hydroxy provides faster increment in pressure and temperature which may minimize the knocking especially at idle conditions (low or no load). Also, ignition delay period reduction yields diminished engine noise. The results show that the addition of hydroxy can significantly enlarge the flammable region and extend the flammability limit to lower equivalence ratios.

At high speeds (1750 rpm) the weakened in-cylinder charge flow and increased residual gas fraction are formed, which block the fuel to be fast and completely burnt. Since hydroxyl has a low ignition energy and fast flame speed, the hydroxyl diesel mixture can be more easily ignited and quickly combusted than the pure diesel fuel.

Thus, improved torques at high speeds can be obtained. Low lean-flammability limit of hydroxy gas allows stable combustion at highly dilute (lean) circumstances. However, it is observed that hydroxy gas cannot have a positive effect on power output at around stoichiometric (richer) conditions.

Since the energy density of hydrogen on volume basis is much lower than that of diesel fuel, the reduced fuel energy flow rate is attained and finally results in the dropped engine torque at low speeds. The impairments of HHO at low speeds can be turned into advantages with the aid of the electronic Module HECU.

Fig 4

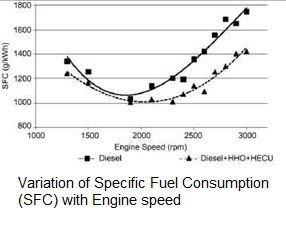

The variation SFC with engine speed is shown in Fig. 4. An average gain of 14% is achieved on SFC by using hydroxyl gas system. Brake thermal efficiency is usually used to symbolize the engine economic performance. The improvement in engine brake thermal efficiency for the hydroxy enriched CI engine is more evidently seen at high speed conditions. The reduction in SFC is due to uniform mixing of hydroxy with air (high diffusivity of hydroxy) as well as oxygen index of hydroxy gas which assists gasoline during combustion process and yields better combustion. This can be attributed to that, at high speeds, the diesel fuel is hard to be completely burnt at lean conditions due to the increased residual gas fraction and poor mixing. Since HHO gains a high flame speed and wide flammability, the addition of hydrogen would help the fuel to be burned faster and more complete at high speed conditions. Also, low ignition energy of hydroxyl air mixture derives diesel fuel even to be burned safely under leaner conditions. However, at low speeds (1750 rpm), low lean-flammability limit prevents hydroxy to have positive influence on combustion efficiency due to mixture requirement around stoichiometric conditions. Increased CR may cause pre-ignition and high volume occupation of hydroxyl causes reduced volumetric efficiency unless HECU is included to the system.

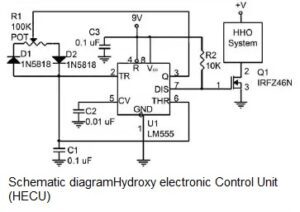

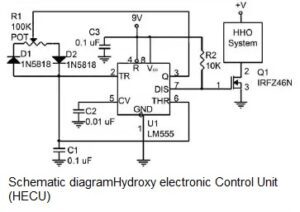

An electronic control unit was designed and manufactured to decrease HHO flow rate by decreasing voltage and current. Experiments depicted that voltage around 7.3 V and current around 5.9 A were suitable values for the engine speed below 1750rpm and data logger was programmed according to these values. HECU was designed according to working principles of a Pulse Width Modulation (PWM) Circuit based on the 555 Timer which is the process of switching the power to a device on and off at a given frequency, with varying on and off times with aid of a Metal Oxide Semiconductor Field Effect Transistor (MOSFET).

IRFZ46N MOSFET was used due to its high electrical current endurance (50 A) and high triggering capacity. Schematic diagram of the circuit and pin descriptions for the 555Timer are shown in Fig 2 and Table 3 respectively.

Fig 2

table 3

Brilliant Invention Gen 20 Hydrogen Generator Oxy-Hydrogen gas is... Full Story

Drop in oil price and Hydrogen. April 22 2020... Full Story

Adjustable Power Supply Adjustable Power Supply 0-48V 60A |... Full Story

MAP / MAF engine sensor operation and engine efficiency-... Full Story

THE ELECTROLYSIS OF WATER TO GENERATE H2 march 26... Full Story

Payment Methods Partner:

© 2023 - Hydrogenfuelsystems pty ltd